CRAC Unit Air Conditioning: Benefits, Principle, Cost, and Components

CRAC Units are highly essential for keeping the heat under control in computer rooms.

What is a CRAC Unit?

CRAC Air Conditioning Unit which stands for Computer Room Air Condition units is very important for the cooling and proper functioning of computer rooms. They are basically located at places where there are a lot of CPU systems like the server stations or IT Rooms.

CRAC Unit generally operates using a Direct Expansion (DX) refrigeration cycle. The whole process of cooling is carried out by passing air over a cooling coil which is filled up with refrigerant.

Benefits of CRAC Units

Starting with answering them, we will first let you know about the benefits of using a CRAC Unit:

- eliminate excess heat

- and stabilize the temperature

- and ensure the proper cooling for proper ventilation for server rooms.

Needs of CRAC Units

After going through the benefits of a CRAC Unit one might be wondering why CRAC Units are needed?

Well! CRAC air conditioning units are inbuilt highly efficient cooling devices that are capable of expelling excess heat, and hence they are needed at places like the server stations.

CRAC units are famous among IT professionals who are regularly searching for ways to make the system highly responsive and scalable.

Several CRAC manufacturers are prevailing in the market, some of them are mentioned as follows:

- Airedale

- Stulz

- Trane

- Vertiv

- York

Working Principle of CRAC Unit

There are three different types of ways in which heat is removed by the system like:

- Air-cooled system

- Glycol/water-cooled system

- Chilled water system

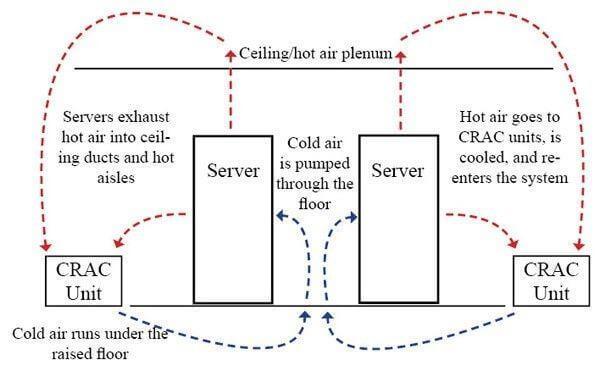

The working principle can be explained with the help of a proper diagram as follows:

The whole system works on the principle of low and high pressures. Once the fans inside the CRAC Air Conditioning units start running a low pressure creates and this helps in drawing in the hot air from outside. Now, this hot air passes through the cooling coil present inside the Unit and gets cooled down. This cooled air is blown back into the room.

The refrigerant liquid is the prime constituent present inside the cooling coil of the CRAC Unit helps in absorbing all the heat and gradually cooling down the hot air.

At the end of the whole process, the heat picked by the cooling agent is carried out to the external condenser. This heat is primarily passed through the compressor where it will be compressed before passing out in the space.

The external condenser system also uses fans to help pass the air throughout the coil which in turn removes heat from the liquid before passing through the expansion valve.

Components Of CRAC Units:

CRAC units are manufactured with a direct expansion system and compressors, directly into the unit. A CRAC unit consists of a cooling coil, a refrigerant, and a compressor. Here is a list of all the components:

- Unit Frame

- Panels [sides, bottom, and top]

- Sound attenuation [absorbing foam/fiberglass insulation sandwiched between the panel skin]

- Access doors to various compartments

- Inspection windows

- Supply and Return air plenum

- Filters

- Fan section

- Energy-efficient fans

- Fan guards

- Variable speed drive

- Motors

- Vibration isolators

- Cooling coil

- Condensate drip pan and pipework

- Condensate pump [if required]

- Reheat coil [if required]

- Humidifier [if required]

- Control/expansion valves

- Control panel and wiring

- Network switch [if using multiple units]

- Compressor

- Range of refrigerant pipework

- Refrigerant [R407A]

- External air-cooled condenser, consisting of,

- Condenser unit frame and panels

- Condenser fans and coils

Here is a detailed description of the system and manufacturing process of the CRAC Air Conditioning Unit:

A. Cooling Medium used in CRAC Units

CRAC units use refrigerants or cooling agents to cool down the hot air from the surroundings and pass out cooled down air into the space. This process is taken care of by the Direct Expansion system which signifies the connection of an independent external connection unit to the indoor CRAC unit via a refrigerant network.

B. Refrigerant used in CRAC Units

R407A is a well-known non-ozone; depleting, a stable refrigerant used in the CRAC Units. This refrigerant is mostly used in low/medium refrigeration systems.

If one could look at a CRAC unit in a two-component system then you can witness that, half of the components of the CRAC unit are located in the refrigerant cycle whereas the other half is located outside which is known as the air-cooled condenser. Due to this kind of intrinsic structure, CRAC units are also known as the split system unit.

There are four different configurations of air conditioning depending upon the working principle of a particular model. They are mentioned as follows:

1. Down Flow Configuration: according to this kind of configuration the hot air from around is sucked inside the CRAC Unit through the top-most part of the unit. The air is then sent through the cooling system and ultimately the cooled down air is sent out through the frontal section of the Unit.

2. Upward Flow Configuration: according to this type of configuration the hot air from the surrounding is sucked in through the frontal opening of the CRAC Unit and then the air is made to run through the cooling system. After the whole process, the cool air is sent out through the topmost section of the unit.

3. Frontal Flow Configuration: this kind of configuration is very common for UPS, IT Rooms, etc. This kind of configuration involves the frontal lower section of the CRAC Unit sucking in the hot and humid air from around and then passing it through the cooling pipework, ultimately sending it out through the frontal upward section of the CRAC unit.

4. Under Floor Supply: The CRAC unit will sit on a frame, usually a plenum, that is installed within the floor void to allow the conditioned air to pass through. Using a ‘down flow’ configuration. The hot air will be drawn through the top of the unit, conditioned, and then discharged into the floor. The conditioned air on the floor will be allowed into the space at the end of the whole process.

CRAC Unit Power Consumption

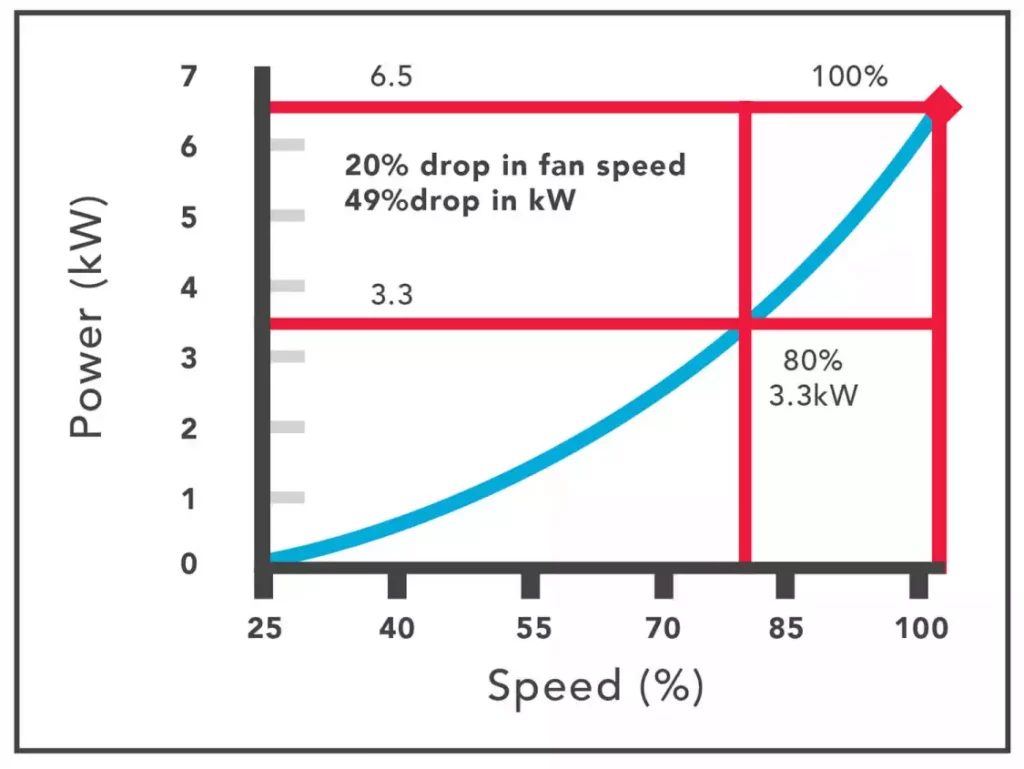

It is a common assumption that half of the air supplied by the CRAC units is generally misdirected to places except the cold aisle. This is to conclude that a leakage flow of 50% is present. Thus, the CRAC units are supplying twice as much chilled airflow than required to satisfy 100% flow through the racks.

Hence making the common assumption a fact. The total cooling power of 2.62 MW is used up for cooling 2.94 MW of heat load. Regardless of the common misconception, the chiller contribution to the energy consumption is not the largest fraction (28%), but the CRAC power consumption is at 42% which is even higher.

Difference Between CRAC and CRAH

Here is a detailed table comparing the features of CRAC and CRAH Air Conditioning Unit.

| CRAC Unit | CRAH Unit |

|---|---|

| CRAC Unit stands for “Computer Room Air Conditioner”. | CRAH Unit stands for “Computer Room Air Handling”. |

| Works on the principle of cooling down the sucked-in hot air by passing it through the cooling pipe-work containing refrigerant. | Works on the principle of using chilled water in the cooling pipework for cooling down the hot air from the surrounding. |

| Consists of refrigerants and compressors. | Consists of chilled water and a control valve. |

| Generally used in homes or IT Rooms. | Generally used in skyscraper buildings |

| They work on the system of direct expansion system | They don’t work on the principle of a direct expansion system. |

| They are also known as split system air conditioners. | They are known as the Chillers because they use chilled water instead of refrigerants. |

| They provide constant volume and only modulate on and off. | CRAH Units can regulate fan speed to regulate a static pressure which gradually takes care of the humidity level and stabilizes the temperature. |

Read More: