Electric Motor Checker EMC 22: Essential Guide for Enhanced Performance

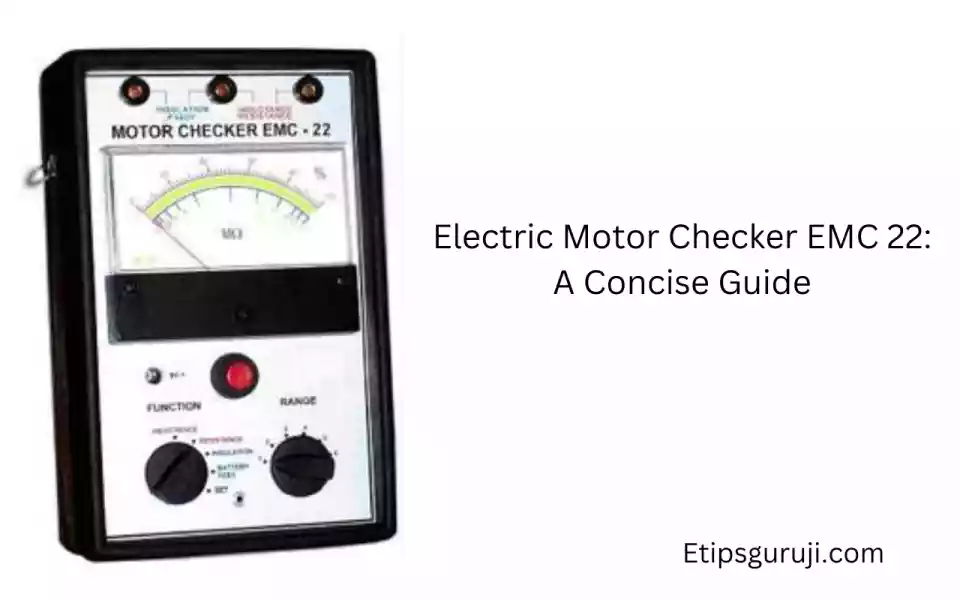

The Electric Motor Checker EMC 22 is a portable diagnostic tool designed for quickly and efficiently detecting electrical faults in motors and other three-phase equipment.

The EMC 22 is particularly useful in assessing the performance of electric three-phase machines, as it can help determine if the issue is electrical or mechanical in nature.

Key Features of the Electric Motor Checker EMC 22 include:

- Insulation resistance measurement

- Identification of open and short circuits

- Detection of loose connections in winding coils

- Identification of internal and ground faults

EMC 22 Overview

The Electric Motor Checker EMC 22 is a diagnostic tool designed for Electrical Engineers to perform quick on-site assessments of electric three-phase machines.

This portable device can help identify various electrical faults that may lead to reduced machine performance, inefficient operation, or tripping of overloads.

Product Specifications

The EMC 22 is a handheld, portable testing device designed for quick inspections and assessments of three-phase electrical equipment.

Intended for on-site fault analysis, the EMC 22 is a highly useful tool for engineers working with motors and other three-phase devices.

Key Features

- Insulation Resistance Measurement: This feature helps identify issues with the insulating materials within the motor, which can result in short circuits or other failures if left undetected.

- Diagnosis of Open and Short Circuits: The EMC 22 can rapidly locate open and short circuit faults within the windings of a motor, enabling prompt remedial action before more severe damage occurs.

- Identification of Rotor Defects: By detecting inconsistencies in rotor performance, the EMC 22 can identify potential issues before they lead to catastrophic failures or significantly impaired operation.

With these features, the Electric Motor Checker EMC 22 provides a comprehensive solution for diagnostics and fault detection in three-phase equipment, ensuring optimal performance and timely maintenance for various industrial applications.

Operating Principles

The Electric Motor Checker (EMC 22) is a versatile instrument designed to quickly detect electrical and mechanical faults in motors, generators, and transformers. Its operation primarily involves three separate modes, addressing different types of faults, such as insulation, open circuits or loose connections, short circuits, and rotor defects.

- Firstly, to measure the battery condition, select the function switch to battery, press the ‘check’ button, and observe the needle deflection. A deflection of more than 70% indicates a good battery[source].

- Secondly, when measuring insulation, connect the test leads to the terminal marked ‘insulation 500v’. The EMC 22 assesses the insulation resistance of the motor, aiding in the detection of issues such as frayed or damaged insulation[source].

- Moving further, the EMC 22 can detect open circuits and loose connections by sensing voltage differences between phases, which may impact motor efficiency and potentially cause overloads[source].

- Lastly, to identify short circuits and rotor defects, the device measures unusual currents and flux imbalances, contributing to the early detection and prevention of motor damage[source].

Testing Procedures

Preparation

Before using the Electric Motor Checker EMC 22, it’s important to prepare the three-phase motor for testing.

While it’s not mandatory to remove the input cable, remember to switch off the input supply breaker to prevent accidents or damages during the testing process.

Identify a convenient spot on the input supply of the motor to take the necessary readings.

Testing Process

The Electric Motor Checker EMC 22 is designed for quick on-site checks of electric three-phase machines.

It helps diagnose potential mechanical or electrical faults that contribute to reduced machine performance, such as inefficient operation or tripping of overloads.

To conduct the test, follow these steps :

- Switch off the input supply breaker.

- Connect the EMC 22 to the motor’s input supply.

- Turn on the device and begin testing according to the provided instructions.

- Analyze the readings to determine any electrical or mechanical faults.

It is essential to follow the manufacturer’s guidelines for the EMC 22 in order to obtain accurate results and maintain the safety of both the equipment and personnel.

Interpreting Results

The Electric Motor Checker EMC 22 is an efficient and portable diagnostic tool for identifying faults in electric three-phase machines, such as motors, generators, and transformers. It is essential to correctly interpret the results of the EMC 22 to diagnose and resolve any issues effectively.

There are three separate operating modes on the EMC 22, each designed to measure different types of faults, including insulation issues, open circuits/loose connections, short circuits, and rotor defects source. The results from each mode can be found on the instrument’s display.

- When checking insulation resistance, the EMC 22 will display a megohm value that represents the quality of insulation. Higher values indicate better insulation, while lower values may signify deterioration or damage in the insulating material.

- For open circuit or loose connection detection, the device will display a numeric value corresponding to the winding coil’s condition. If the number is within the expected range, then the winding coil is fine. However, if the displayed value deviates significantly from the expected range, it may indicate an open circuit or loose connection issue.

- When identifying short circuits or rotor defects, the EMC 22 will display an indication of the fault location and severity.

Troubleshooting and Maintenance

Electric Motor Checker EMC 22 is an essential diagnostic tool for electrical engineers that helps diagnose and maintain electrical machines.

Common Issues

Several common issues can be quickly detected using the EMC 22, such as:

- Inter-turn shorts

- Rotor bar problems without dismounting the rotor

- Blowholes or cracks in rotor bars

- Inefficient operation and tripping of overloads

Preventative Measures

To prevent and maintain the health of electrical machines, a few essential preventative measures can be followed:

- Regular inspection of machine performance to detect any sign of degrading efficiency, such as operational inefficiencies and overloads that may indicate mechanical or electrical faults.

- Using the EMC 22 for on-site checks to immediately detect and address electrical faults without having to dismantle the equipment.

- Periodically measuring battery condition and insulation of the electrical machines using the EMC 22.

Implementing these preventative measures, along with the use of the Electric Motor Checker EMC 22, can help ensure the optimal performance and longevity of electrical machines.

Industry Applications

The Electric Motor Checker EMC 22 is a versatile diagnostic tool utilized in various industries for quick on-site evaluation of electric three-phase machines.

Its primary function is to detect electrical faults that may affect machine performance, such as inefficient operation or tripping of overloads.

Some common industry applications of the EMC 22 include:

- Detecting electrical faults in motors and other three-phase equipment, such as short circuits, open circuits, and insulation damage.

- Checking the quality and condition of electric motors that have been in storage prior to installation.

- Assessing the performance and efficiency of various machines, including gear pumps, cranes, and conveyors used in industrial automation.

Besides being portable and easy to use, the EMC 22 offers three separate operating modes, making it capable of measuring different types of faults, such as full insulation, open circuits or loose connections, short circuits, and rotor defects.

In summary, the Electric Motor Checker EMC 22 is an indispensable tool for electrical engineers and technicians working with three-phase electrical equipment.

Read More: