Thrust Bearing – 6 Design Types, Working, and Applications

Bearings!!! All of us know they are the ball-like structures which are an important part of rotary machines. And among all bearings, there is a bearing called Thrust Bearing which is quite a valuable piece of machinery for high-end rotatory parts.

This post states all about the thrust bearing, its types, applications, and their working. So, let’s find out some technical and mechanical information related to all types of thrust bearings.

What is Thrust Bearing?

These are the mechanical parts that are a type of rotatory bearing and serve the same functions as other bearings i.e. permit rotation between the parts. But in case of the thrust bearing, it prevents the shaft movement along its length. Therefore, it works as the rotary medium for the axial loads only.

They are commonly used to deliver or permit rotation in one or both directions. This means a single action thrust bearings carry the load in one direction while double action works bidirectional.

As they have numerous applications, so they are available in several designs and configurations. So, let’s take a close look at various configurations of thrust bearings.

People Also Read:

- How to Hotwire a Car? | 3 Best-Known Cheat to Hotwire a Car

- Digital Voltmeter- Principle, 4 Basic Types, Applications, Merits & Demerits

Thrust Bearing Sizes and Configuration

Altogether, these bearings are available in various configurations such as the ABMA Inch series, ISO Metric series, and other bearing numbers.

ISO Metric System

In this metric system, the boundary dimension of rolling bearings is standardized globally. For instance, ISO is a French acronym for the International Organization for Standardization. This facilitates its use, mass acceptance, and understandings throughout the globe.

The parameters that are included in this ISO metric system are the bore diameter, outside diameter, width, and chamfer dimensions.

To calculate the ISO value, formula is

D= d+fDd0.9

B= fB * (D-d)/2

- D= Outside diameter

- d= bore diameter

- B= width (also termed as T for height)

In addition, the general diameter range for any bearing is from 0.6 mm to 2500 mm.

The following tables give you the common configuration and size of thrust bearing in terms of outside diameter and width/height.

Table 1: fD values for Thrust Bearings

| Diameter Series | 0 | 1 | 2 | 3 | 4 | 5 |

| fD | 0.36 | 0.72 | 1.20 | 1.84 | 2.68 | 3.80 |

Table 1: fT values for Thrust Bearings

| Height Series | 7 | 9 | 1 |

| fT | 0.9 | 1.2 | 1.6 |

ABMA Inch System

ABMA is the acronym for the American Bearing Manufacturers Association. This system handles the number of values for the tapered type of bearings. Unlike the ISO metric system, ABMA values are defined by some specific numbers and symbols for new designs.

The following figures state the number of bearings for the ABMA inch system.

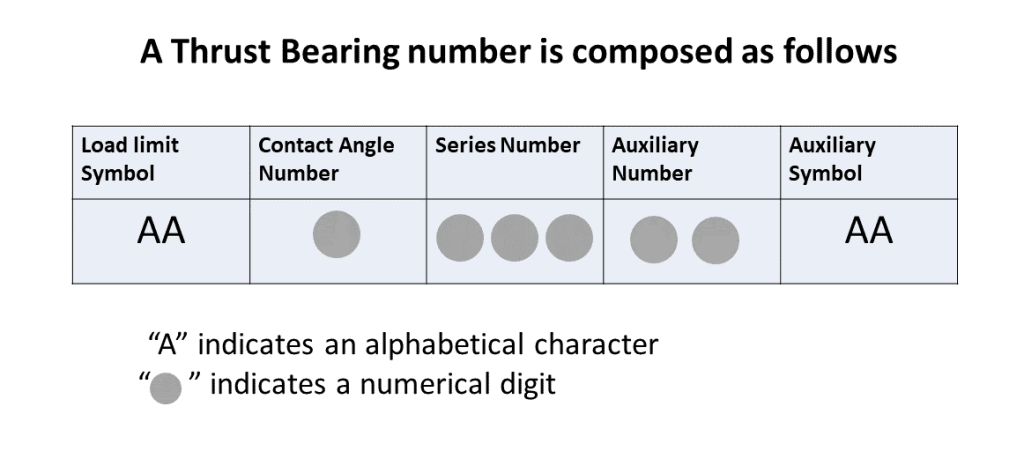

Other Bearing Number

As ISO has its own standardization method for the numbers, therefore, many countries use their own standard chart or bearing numbers for the manufacturing of bearings. In the majority of bearing number configuration, the company uses two units such as width series symbols and diameter series symbols.

For thrust bearings, the various combination of diameter and height symbols is employed to specify the configuration of it.

The following tables state the formulation of bearing number for thrust bearings.

| Bearing Types | Sample Brg. | Type No. | Height No. | Dia. No. | Bore No, |

|---|---|---|---|---|---|

| One Direction Flat Seats | 51124 | 5 | 1 | 1 | 24 |

| Two Direction Flat Seats | 52312 | 5 | 2 | 3 | 12 |

| One Direction Self-align seats | 53318 | 5 | 3 * | 3 | 18 |

| Two Directional Self-align Seats | 54213 | 5 | 4* | 2 | 13 |

| Spherical Thrust Roller | 29230 | 2 | 9 | 2 | 30 |

Note: For single-action (uni-directional) inch and the metric system are capable of light load axial work. But most of the heavyweight bearings are designated using angular contact series.

Common Thrust Bearing Design (Types)

In broad, there are six types of thrust bearings designs which are:

- Thrust Ball Bearings

- Cylindrical Thrust Roller Bearings

- Tapered Roller Thrust Bearings

- Spherical Roller Thrust Bearings

- Magnetic Thrust Bearings

- Fluid Film Thrust Bearings

So, let’s dig deeper in each type of thrust bearings and know them in details

Thrust Ball Bearings

These are the simplest of all the types of thrust bearings and they are mostly employed in rotatory parts where the very little axial load is required. While the miniature thrust ball bearings sizes range from 2 mm to 340 mm.

How Thrust Ball Bearing Works?

They serve the same purpose that a ball bearing does, i,e, it reduces the friction but only supports the axial loads.

In most cases, they have at least two races filled with bearing balls to transmit axial loads. In general, one race is attached to the stationary part while others govern the movement on the axial line.

However, ball bearing that has a double-row design can bear more axial load as compared to single row ball bearings. For instance, the load-bearing capacity would be around 2 times the single row ball bearing.

Application of Thrust Ball Bearings

- The skateboard wheel uses both axial and radial thrust ball bearing.

- Some office chairs

Cylindrical Thrust Roller Bearings

A cylindrical roller thrust bearing is a type of roller bearing which permits the rotations between two parts of high axial load. And the smallest cylindrical thrust roller bearing is of about 45mm bores.

How Cylindrical Thrust Roller Bearing Works?

When an axial load is placed in between two bearing rings with rollers then the relative motion of the rings causes the rolling elements to roll.

This also makes it relatively less resistant as compared to the load because of the fine weight distribution system. And aligned rollers also help to maintain the steadiness and abrupt any sliding movement of the axial load.

The fine weight distribution works profoundly because the outer load is continuously re-distributed which makes it more load bearable. And as per data, less than half of the total rollers carry the load.

In general, these cylindrical rotary parts use cylinders that have an elongated body than the diameter. However, they have a lower capacity and higher friction when they are held by an axial load. This also leads to regular maintenance because the ball bearing inside the cylinder usually gets misaligned.

Applications of Cylindrical Thrust Roller Bearings

These types of bearings are commonly useful in components such as

- Automotive industries

- Industrial machinery

- Marine engines

- Aerospace shuttles

Tapered Roller Thrust Bearing

A rolling-element bearing that uses tapered roller bearing to handle both axial loads is termed as tapered roller thrust bearings. They are capable of handling heavy axial loads because of their low frictional operation.

How Tapered Roller Thrust Bearing Works?

In general cases, they are available in a cylindrical form which consists of the inner and outer ring (called races) that are running in coned rings along with tapered rollers. They are arranged in such a way that the surface of the rollers meets at the axis of the bearing.

The principle of heavy load action is due to the counteraction heavy load method. So, in each row of the tapered thrust bearing, it can only take high axial loads from one direction.

However, due to the use of a counteract axial load, it can achieve a high axial load from multiple directions analogous to induce weight.

Applications of Tapered Roller Thrust Bearing

They are generally used in the wheel of cars as back-to-back pairs. This will distribute the axial forces in either direction.

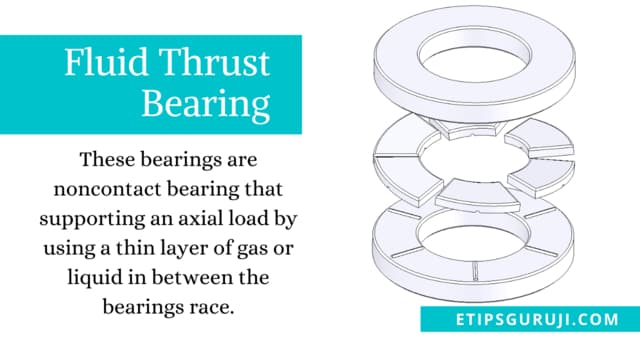

Fluid Thrust Bearing

These bearings are noncontact bearing that supporting an axial load by using a thin layer of gas or liquid in between the bearings race. These thin layer films act as the lubricants reduces the sliding friction.

This all together leads to less wear-tear of the surface along with minimum vibration. This is why they are generally employed in the high axial load with high speed and precision.

There are basically two types of fluid thrust bearings; Hydrodynamic Fluid Bearings, and Hydrostatic Fluid Bearing.

How Fluid Thrust Bearing works?

As there are two types so there are two underlying principles.

The working of a hydrostatic fluid thrust bearing is governed by the application of positive pressure. These bearings are employed with a hydrostatically-lubrication under pressure between the moving surfaces. Meanwhile, this adjusts the fluid pressure and consumption according to the rotation speed and shaft load.

While in fluid-dynamic thrust bearings, the bearing surfaces (both the stationary and rotating surfaces) have thin lubrication which is usually oil, air, or some processed fluids.

This lubrication layer makes sure that both the surfaces have no contact during the operations. This pressure between the separation is created by the relative motion of the surfaces.

Applications of Fluid Thrust Bearing

Generally, these are some application that is commonly seen in components such as

- Compressors

- Large turbines

- Gearboxes and pumps in the power generation

- Turbines of oil, gas, and chemical processing industries.

- High-precision applications such as in measuring, testing, and machine tool engineering.

Spherical Roller Thrust Bearing

Spherical Roller Thrust Bearing is nothing but a rolling-element of thrust type that allows very low frictions and facilitates rotation.

But the most important aspect is that these are specially designed to handle the heavy axial load. And that’s the reason why they have the highest load rating capacity of all thrust bearings.

How do Spherical Thrust Bearings works?

These bearings have rolling elements that permit rotation with low friction in both types of loads i.e. axial and radial loads. However, they are only capable of working unidirectional.

This means that these bearings can sustain axial loads in one direction and meanwhile acting on radial loads. In general, a spherical roller bearing is specially designed to be raceways and asymmetrical rollers.

While talking about its major component, it has a shaft washer, a housing washer, asymmetrical rollers, and a cage.

Applications of Spherical Roller Thrust Bearings

These are the following applications of spherical roller thrust bearing:

- Water turbines

- Marine propulsion and offshore drilling

- Extruders for injection molding

- Cranes and swing bridges

- Pulp and paper processing equipment

- Gearboxes

Magnetic Thrust Bearing

Magnetic Bearing is a type of bearing that supports loads without any physical contact. There are basically two types: one is active magnetic thrust bearing and the other is the passive magnetic thrust bearing.

An active magnetic bearing uses controlled electromagnets (which act as a magnet on the application of electricity). While a passive magnetic thrust bearing uses permanent magnets, that’s why it doesn’t require any additional input power to operate.

How do Magnetic Thrust Bearings works?

The working of both the type of bearing depends upon the principle of magnetic levitation. This is a phenomenon in which a magnetized object is levitated by the magnetic force of opposite ends.

So, in this, various pairs of magnets are placed over the opposite side of the body in such a way that the center rotator gets enough force to keep it in moving in the central position.

However, in a combined design of magnetic bearing— permanent magnet bearing is used to carry the static load. While, in case of different types of load, a variable magnetic field is required which can only be achieved by varying the current of an active magnetic thrust bearing.

Application of Magnetic Thrust Bearings

Magnetic bearings are used in several industrial applications such as

- Petroleum refinement

- Natural gas handling

- Uranium enrichment

- Electrical power generation

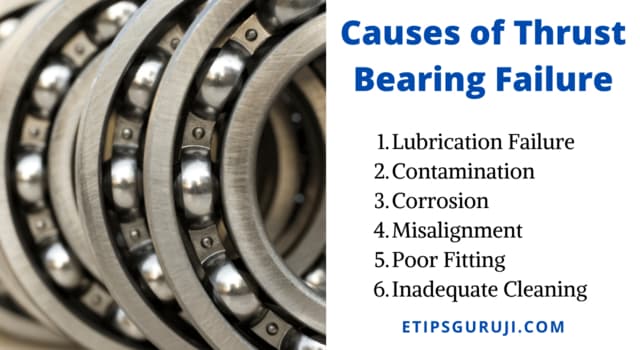

Causes of Thrust Bearing Failure

These are some of the common cause of thrust bearing failure, which is listed as:

1. Lubrication Failure: The number one reason for the thrust bearing failure is the lubrication overuse. With the passage of time, the lubricant oil tends to degrade which can increase the friction. This all leads to heating and other wear-tear of the thrust bearing parts.

2. Contamination: The continuous working of these heavy-duty bearing can catch dirt, sands, and other contaminants with time. Some contaminants such as water can cause the lubrication oil to seep-out the bearings. While contaminants such as dirt and sands increase the resistance.

3. Corrosion: This is also another reason for these bearing failure. And when the rotatory bearings are held in the humid environment then it can cause more corrosion of the thrust part (majorly the shaft).

4. Misalignment: Some bearing such as cylindrical thrust roller bearing and ball bearing are more prone to misaligned with the application of unappropriate axial load.

5. Poor Fitting: If in case the shaft is not of right dimension then due to tightening (or due to loose) it can not only make bearing to get wear-off with time but also make whole equipment fail.

6. Inadequate Cleaning: At last, as you know every equipment needs maintainers because with time the friction can make them slow and home of dirt. So, if a thrust rotary machine is not cleaning in their vital time of use, then it definitely harms its functionality.

Also Read:

- Why Won’t My Car Start- 11 Basic Reason Along With Solutions

- Types of Transformer (Categories Wise) – Working and their Applications

Difference Between Thrust Bearing and Journal Bearing

Journal bearing is also called sleeve bearing. They use the pressure wedge of fluid to ease the movement in between the rotating shaft and the bearing. Journal Bearings get their name due to the solid shaft support which is called a journal that is capable of bearing resistance. Moreover, they have another softer part that matches the journal is called the bearing pad.

Now, what’s the difference between journal bearing and thrust bearing?

A journal bearing allows the shaft to rotate while holding it in a fixed horizontal position. On the other hand, a thrust bearing prevents the shaft movement along its length while it rotates.

While Talking about journal bearing, on rotation, it creates high pressure in the oil film which supports the journal which is again analogous to the load. Therefore, when the load on the shaft varies, the high pressure also varies. This also makes journal bearing more shockproof and load bearable.

And this is why they can run forever, till any internal tearing does not happen. While in case of the thrust bearing, the axial load depends upon which type of thrust bearing is in use. Moreover, they have a specified range of working for weight load.

With this, our post on thrust bearing ends here. But the following are some questions that people generally search on Google.

General FAQ

What causes thrust bearing failure?

Ans. The major cause of thrust bearing failures is lack of lubrication, excessive dirt/contamination, corrosion development, misalignment of the shaft with the body, and inadequate cleaning of internal parts.

What are thrust pads?

Ans. Thrust pads are also called tilting pad. These pads are designed to transfer high axial loads from rotating shafts. The other major function of these thrust pads is reducing the minimum power loss and resistivity.

What is the use of thrust bearing?

Ans. They have a wide application but most commonly employed in the automobiles for the directional movement with radial loads. Other common uses are in skateboards, industrial machinery, and also in aerospace thrusters.

Where is the thrust bearing in a car?

Ans. They are present in the crankshaft of a car. They are usually at the rear center of the car but varies with engine design and placement. These thrust bearings are responsible for the fore-after gap-control axial movement.